Thread: Triac Z height issues

-

01-12-2023 #11

video

https://youtu.be/stbWpra7O_4

so you can hear the z stepper moving the z axis

-

03-12-2023 #12

All thoughts welcome

-

03-12-2023 #13

Any chance that it is a coupling or pulley slipping? Engraving - especially if you are V-engraving - tends to generate a lot of Z movement which might be aggravating something? I am assuming that nothing in the settings has changed.

-

04-12-2023 #14

-

04-12-2023 #15

I wondered if you're getting issues from having the boards sitting on that pink bubblewrap. It's antistatic, hence may have some level of conductivity - maybe even enhanced by humidity - so it could feasibly be affecting the connections on the underside of the PCBs. Since you seem to be getting noise related issues, I'd suggest replacing that with something a bit more inert. In an ideal world you'd screw the PCBs down with spacers off a backboard of some kind, so nothing touches the backs of the PCBs. But for starters you could always try a bit of hardboard or MDF in place of the bubblewrap? Easy to try even if it's not the cause of the problem!

-

07-12-2023 #16

-

07-12-2023 #17

heres an interesting development.

so when the z is at its height it would be machining at i get this z movement issue. if i lower the z right down to near the table, in a position it wouldn't be machining at i dont get the z issue.

so am now wondering if its some kind of cable issue. about a year ago i did have a cable break on the inside on the atc, the years of movements must have broken the cable.

-

07-12-2023 #18

i appear to be finding more issues than solutions at the moment!!

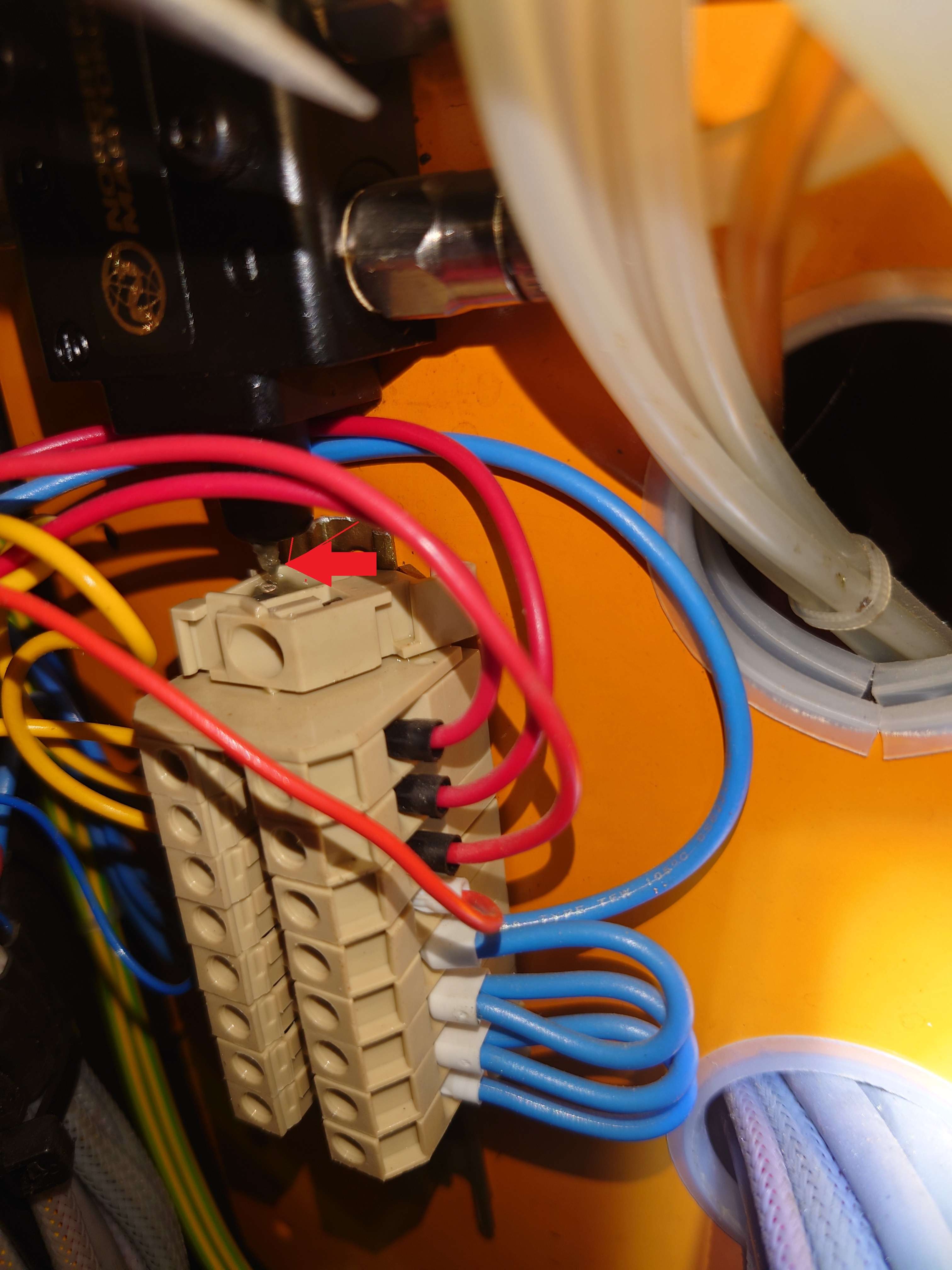

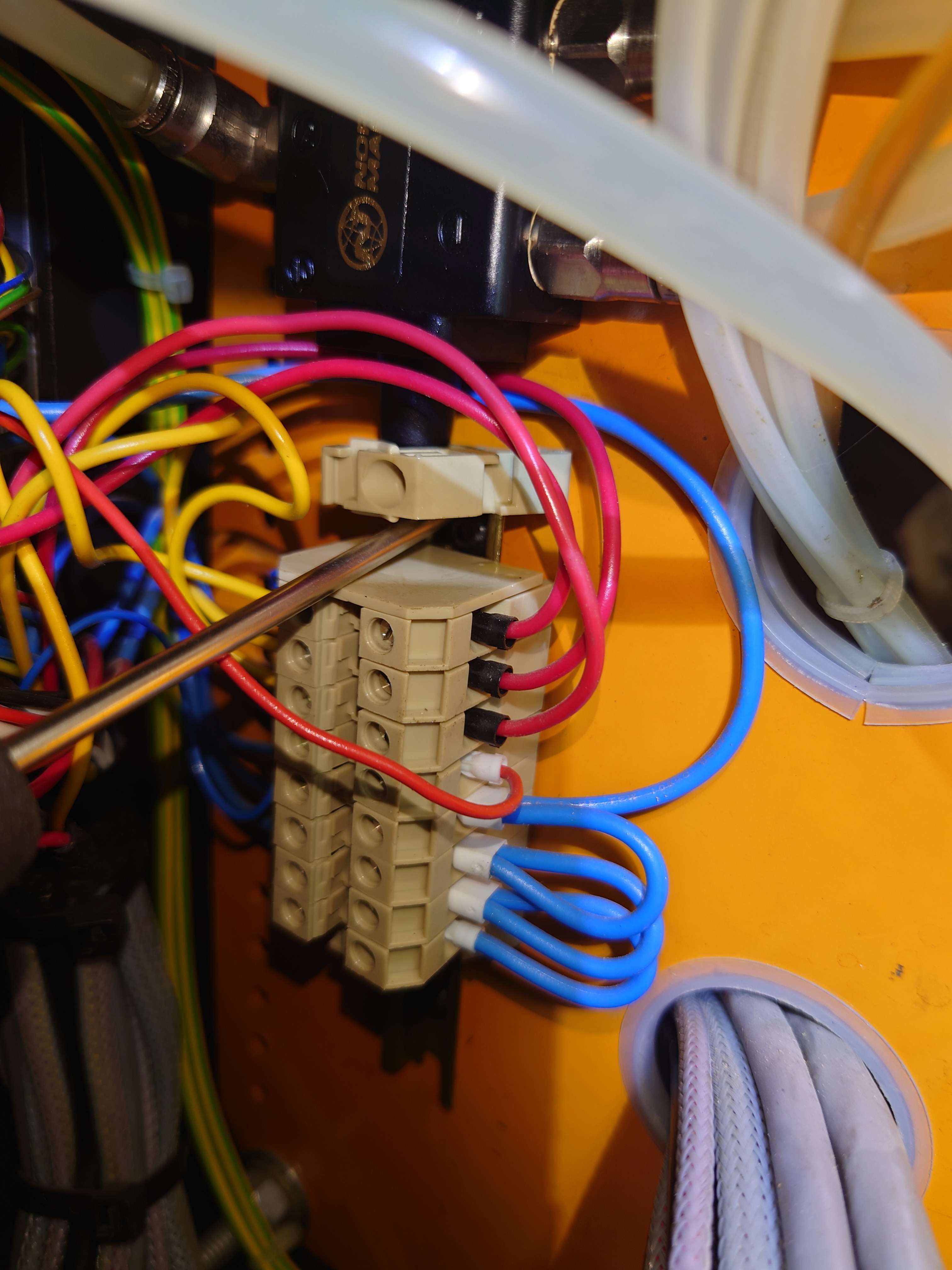

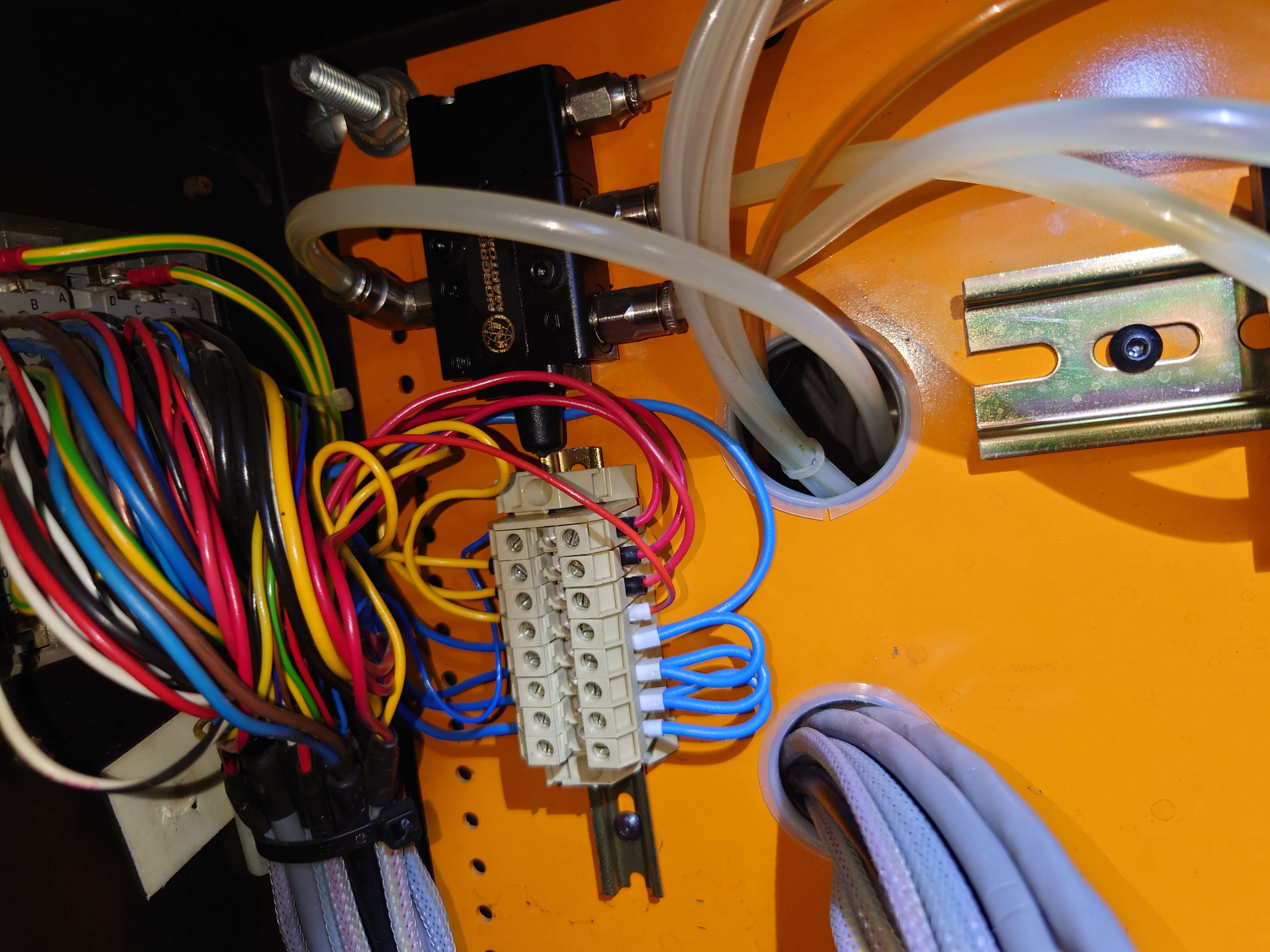

just opened the black box at the back of the machine and noticed the below.

goo coming from the black hose connector block and then the electrical block below is wet. its gone all the way to the bottom connector.

Thread Information

Users Browsing this Thread

There are currently 5 users browsing this thread. (0 members and 5 guests)

Similar Threads

-

Gantry to bed height.

By m.i.k.e in forum Gantry/Router Machines & BuildingReplies: 20Last Post: 05-07-2020, 05:46 PM -

Tool height sensor.

By Ollie78 in forum General DiscussionReplies: 10Last Post: 27-06-2019, 09:32 PM -

Z axis height setter

By phill05 in forum General DiscussionReplies: 7Last Post: 29-11-2016, 01:14 PM -

Z Height - Max?

By Chaz in forum Gantry/Router Machines & BuildingReplies: 6Last Post: 04-02-2016, 11:18 AM -

Height Mapping?

By Tenson in forum General DiscussionReplies: 3Last Post: 26-10-2012, 11:40 PM

Reply With Quote

Reply With Quote

Bookmarks